Machine Link™

QUICK Serve

Streamlines the process of remotely sending and receiving CNC programs.

Machine Link™ QUICK Serve is a shop-floor automation package that allows machinists to remain at their machines and stay focused on making parts. It will increase shop productivity, quality, and machine-tool utilization while also reducing scrap and downtime. The result is improved efficiency and ultimately, more happy customers!

Machine Link™

QUICK Serve

Simultaneously monitor up to 3 machines

QUICK Serve

PLUS

Simultaneously monitor up to 20 machines

QUICK Serve

PRO

Simultaneously monitor up to 64 machines

Overview

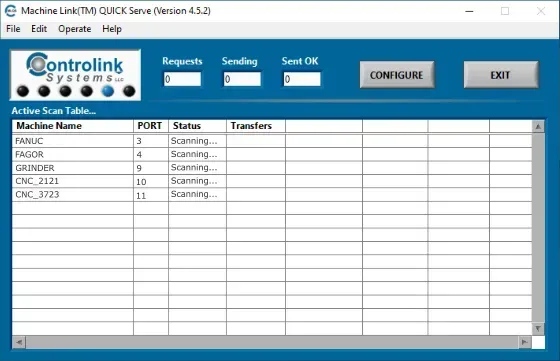

Machine Link™ QUICK Serve continuously scans all machines for file requests made across wireless or wired serial connections. When a remote request is received, the requested CNC file is served directly back to the machine tool control - just like magic!

Machine operators initiate all file requests without needing to leave their machine or manually interact with the PC. The request is initiated from the machine tool control at the shop floor level using simple keywords embedded into the CNC Program Request file. The keyword configuration is extremely flexible and will accommodate all CNC machine tool controls ‐ the only limitation is your creativity!

Machine Link™ QUICK Serve will return the latest engineering-approved file without the operator ever leaving their machine. Keeping operators focused on making parts, and not walking through the shop, will immediately increase your shop's efficiency.

Program edits made at the machines can be sent directly back to engineering for review. Useful edits can be adopted so the CNC programs become more and more efficient. Better CNC programs will also reduce scrap and create a safer work environment.

Machine Link™ QUICK Serve works with old and new CNC controls! It will work in any shop ‐ including your shop ‐ so don't delay, GET LINKED today!

How it Works

Remotely receiving CNC programs at the machine tool control is simple!

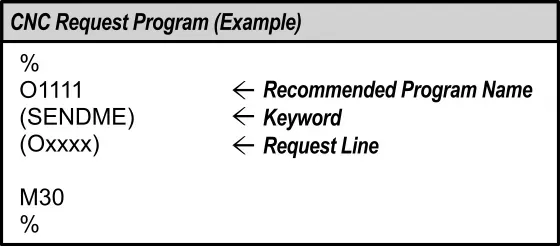

From the CNC machine tool control, open the CNC Request Program (O1111)

Enter the desired CNC file name into the Request Line

Output the edited (O1111) program from the machine tool control

Prepare the machine tool control to receive the desired CNC file

After a short adjustable delay, Machine Link™ QUICK Serve will serve the requested CNC file back to the machine tool control

Note: Email/Text MSG support is an optional feature that allows file requests to be emailed or sent via text message directly to Machine Link™ QUICK Serve, and then quickly served to the specified CNC machine tool control. This is the ideal solution for machines that communicate in one direction (to the control), such as ADR BTRs.

Benefits

IMPROVE PRODUCTIVITY

Boost your productivity by allowing machinists to request files remotely, never having to leave their CNC machine.

MAXIMIZE CNC EQUIPMENT UTILIZATION

CNC programs can often be improved, so if you edit your CNC program while at the machine, you can send it off for internal approval to become the starting point of your next download.

MAXIMIZE CNC EQUIPMENT UTILIZATION

Requesting files remotely helps to keep your setup time low and your machine utilization high.

MANAGE CNC FILE REVISIONS

Put engineering in full control to quickly review and manage shop-floor changes to help improve overall shop efficiency and safety.

WORK SAFER AND SMARTER

Improve safety by keeping machine-side edits to a minimum and using GCODE that is ready to run.

CUSTOMIZE THE CODE

We are willing to customize the software for your shop to streamline installation and deliver even greater impact.

Help

Machine Link™ QUICK Serve is loaded with helpful information about its features.

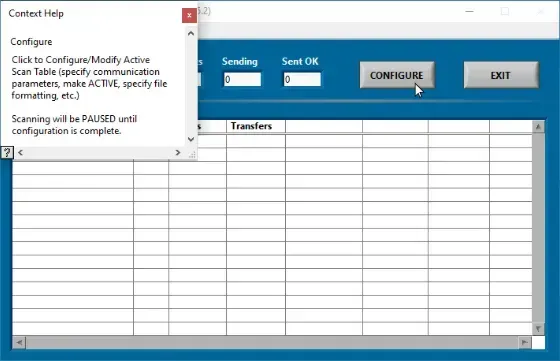

From the tool bar select [Help], and then [Show Help] to activate a useful help window. When this feature is active, Machine Link™ QUICK Serve will display a descriptive help message whenever the cursor is moved over a control.

Tip: Check out our training resources!

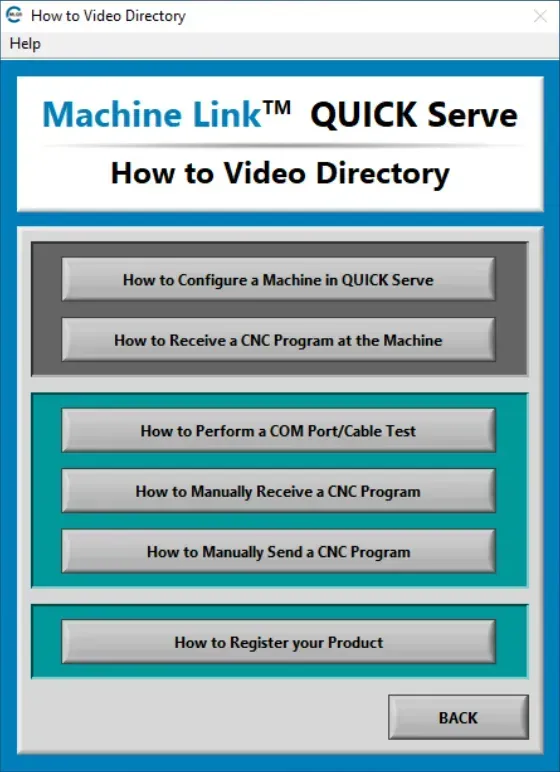

Machine Link™ QUICK Serve also includes a built-in How to Video Directory that provides helpful videos for learning how to configure machines in Machine Link™ QUICK Serve, receive CNC programs, register your product, and more!

From the tool bar select [Help], and then [Show Help] to activate a useful help window. When this feature is active, Machine Link™ QUICK Serve will display a descriptive help message whenever the cursor is moved over a control.

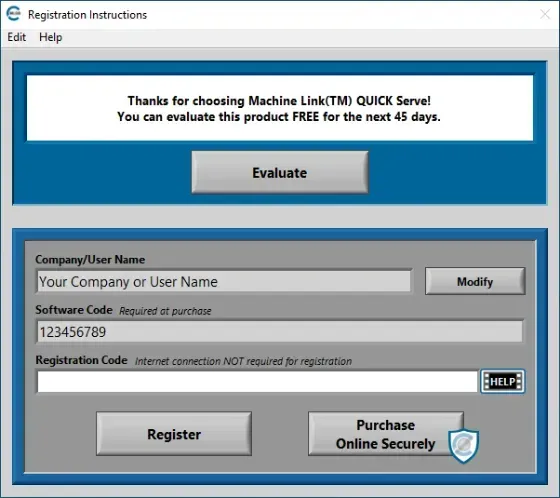

Registration

Registering your software is quick and easy and can be done through Machine Link™ QUICK Serve's Registration screen by clicking [Purchase Online Securely] and entering your purchasing information.

Don't have an internet connection where Machine Link™ QUICK Serve is installed? Click the [Buy Now] button above and enter the "Software Code" shown on Machine Link's Registration screen.

Your "Registration Code" and order details will be emailed to you immediately following credit card processing.

Once your Registration Code has been received, enter it and click [Register].

Need help? Call us at (800) 838-3479.

Customer Comments

"The QUICK Serve DNC software continues to serve us well. With our original DNC software, operators would have to make several trips from their machine to the computer to send a program to their machine. To send a corrected program back from the machine to the system was such a hassle, that most of the time the corrected copy wouldn't get sent back and saved, causing the program to again be fixed when sent back out. The QUICK Serve DNC system has eliminated all those problems. From the machine, our operators now retrieve the CNC program and never has to leave the machine. To send back a corrected program, once again they do not have to leave the machine and all our programs sent back, are temporally saved into an Engineering folder so our CNC Engineer can review the changes to be sure they are correct before moving them into our CNC program library. Installation couldn't have been easier. You walked me through everything, including recommending hardware that fit my particular needs... If I could change anything I wanted on how the QUICK Serve DNC system works, I would not be able to come up with any changes. Thanks for providing this product which has made my job so much easier over the years."

— Steve Araujo

Ametek, Inc.

Resources

United States

24545 Lela Dr.,

Lawrenceburg, IN 47025

© 2024 Controlink Systems LLC

Website Designed & Created by Controlink Systems LLC

Customer Comments