Machine Link™

PLUS

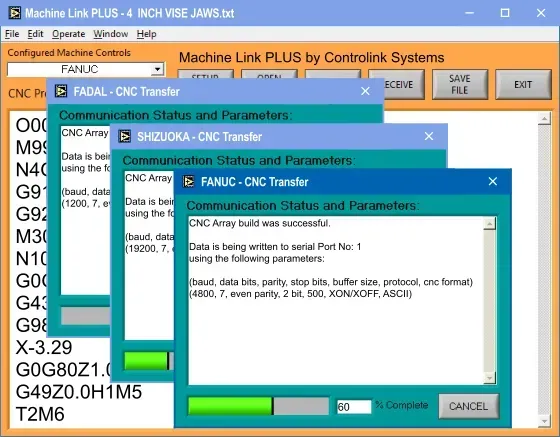

Streamlines the process of sending and receiving CNC programs simultaneously across multiple CNC machines.

Includes all the features of Machine Link™, PLUS allows six simultaneous communication sessions.

Machine Link™ PLUS is very easy to use, is extremely reliable, and will communicate with every CNC machine in your shop that supports standard RS-232 serial communications.

It can actually feed six machines simultaneously and still receive from a seventh!

Like Machine Link™, PLUS can be used to edit, print, upload, and download CNC program files. It is easy to configure and supports all standard character sets (ASCII, ISO, and EIA). It will also drip feed most CNC machines. The software runs on all versions of Windows from Windows XP up (including Vista) and each copy can be configured for an unlimited number of machines.

Overview

Machine Link™ PLUS is identical to Machine Link™ , but it supports six simultaneous communication sessions, sending data to machines, and can be receiving from a seventh CNC machine.

Machine Link™ PLUS requires an available COM Port for each CNC machine tool. There are many hardware options, including wireless communication ports.

Need help picking the best option? Contact us at (800) 838-3479.

Machine Link™ PLUS is ideal for servicing a group of CNC machine tools from a single computer when some of the jobs require drip feeding the machine for an extended period of time.

While one job is active, others can still be started; you don't have to wait for other jobs to end.

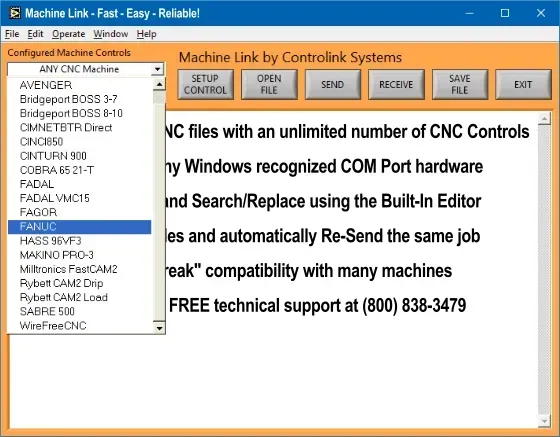

Machine Link™ PLUS can be configured to communicate with any machine in your shop.

It can also be configured for an unlimited number of different machine controls. Simply select the control name from the drop down list box and Machine Link™ PLUS is ready to send and receive CNC program files using the communication parameters associated with that CNC machine tool.

How it Works

Machine Link™ PLUS is designed to be fast, efficient, and easy to use.

A typical session involves either sending an existing CNC program to a selected machine control or receiving a CNC program from a machine control.

Sending CNC programs to a machine tool is simple:

Select the Machine Control to communicate with from the drop down list box

[OPEN] the CNC program file you want to send or type one into the editor

Prepare the machine tool to receive the file and click [SEND]

Machine Link™ PLUS will send the file using the configured communication settings

Pro Tip: Machine Link™ PLUS can also be used to send the same file repetitively without additional operator intervention - the same file is sent again and again each time the [CYCLE START] button is pressed at the machine tool. The operator never has to leave the machine tool to resend the job. The [Send Loop to CNC] option is initiated by selecting [Operate] from the menu bar and then choosing [Send Loop to CNC]. Simply click [CANCEL] to terminate the loop once the desired number of parts has been made.

Pro Tip: It is also possible to send very large files directly from disk without opening them into the editor (this feature conserves computer memory). From the menu bar select Operate, then choose Select & Write File from Disk (or press CTRL+W). You will then be prompted to select the CNC file to transfer. The entire file will be transferred but only small portions of the file will ever be brought into memory enabling large file transfers using any shop computer.

Receiving a CNC program from a machine tool is just as simple:

Select the Machine Control to communicate with from the drop down list box

Click [RECEIVE] to prepare Machine Link™ PLUS - send the file from the machine control

Machine Link™ PLUS will receive the CNC file and place it in the CNC Contents Window

Click [SAVE FILE] to store the program to a file name and location of your choice

Built-In Editor

Machine Link™ PLUS is equipped with the editing features you need to easily create, edit, print, and manage all of your CNC program files.

Search and Replace capabilities are also available to simplify making speed/feed and other modifications to the entire CNC file or a selected block of text.

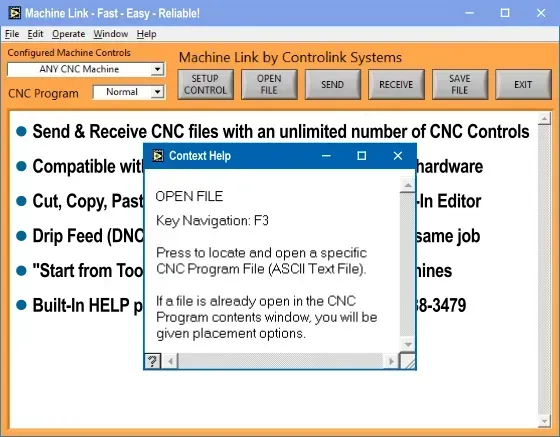

Click [OPEN FILE] to load a CNC program file into the Machine Link™ PLUS editor window. If a file is already loaded, Machine Link™ PLUS will prompt you to either replace the current file [REPLACE] with the selected file or to [MERGE] (insert at last cursor position) or [APPEND] (place on end) the selected file with the current CNC program.

The merge location is clearly displayed for your convenience. This makes it easy to combine new and existing CNC code.

Click [SAVE FILE] to save the contents of Machine Link's™ editor window to a file name and location of your choice. By default, Machine Link™ PLUS will write the entire CNC program to the file. However, if you select a block of text with the cursor prior to clicking [SAVE FILE], Machine Link™ PLUS will enable you to save only the selected block of text or the entire contents to a file name of your choice.

Printing saved CNC progam files from your computer is easy. From the tool bar select [File], and then [Print CNC File]. Machine Link™ PLUS will print the selected file to your default printer (instant hardcopy for the job folder). It is no longer necessary to edit/copy/paste to a different piece of software just to get a hardcopy of your CNC program.

Machine Link™ PLUS will also sort and print directory listings which include file name(s), their size, and last modificaiton date/time. The directory listing is printed with a header clearly indicating the name of the selected directory and the date/time of printing. This is an awesome feature to help manage your CNC program files. From the menu bar select [File] then choose [List DIR Contents]. Machine Link™ PLUS will automatically display the last directory that files were either retrieved from or saved to.

Help

Machine Link™ PLUS is loaded with helpful information about its features.

From the tool bar select [Help], and then [Show Help] to activate a useful help window. When this feature is active, Machine Link™ PLUS will display a descriptive help message whenever the cursor is moved over a control. As an example, the below help message was displayed when hovering over the [OPEN FILE] button.

Tip: Check out our training resources!

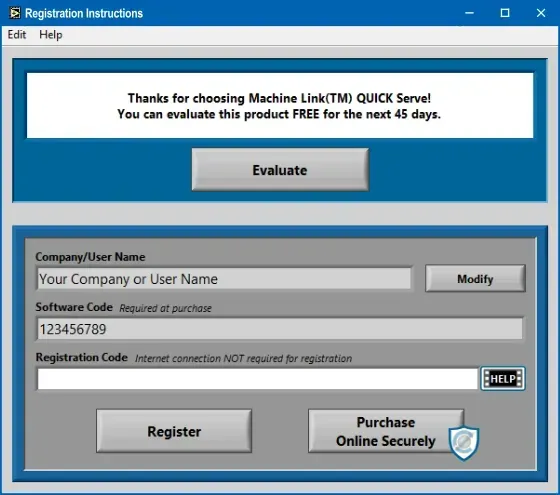

Registration

Registering your software is quick and easy and can be done through Machine Link's Registration screen by clicking [Purchase Online Securely] and entering your purchasing information.

Don't have an internet connection where Machine Link™ PLUS is installed? Click the [Buy Now] button above and enter the Software Code shown on Machine Link's Registration screen.

Your "Registration Code" and order details will be emailed to you immediately following credit card processing.

Once your "Registration Code" has been received, enter it and click [Register].

Need help? Call us at (800) 838-3479.

Customer Comments

"Machine Link™ PLUS has yielded a definite cost savings. It is now much easier to plan jobs and it's a definite benefit for us being able to send to three or more machines at the same time. We have two shop computers each with a copy of Machine Link™ PLUS - one has direct connections to four vertical mills and other feeds six different CNC lathes. The operators in the shop really like using it."

— Richard Stevens

Tech Tool Inc., Tipp City, OH

"Thank you so much for your great support and Machine Link™ software. I had spent many frustrating hours trying to send files to my Bridgeport without success. I even paid a Bridgeport representative who was unable to make the link. You and your software made it happen quickly and effortlessly. I highly recommend this product to anyone who has experienced the same situation."

— Steve Clayton

Clayton Guitar Picks, (Steve Clayton, Inc.) Talent, OR

"We use Machine Link™ everyday to send and receive files from our Mazak, Okuma, Fadal, and Partner (Milltronics) controls. Guy Hughes of Controlink Systems made it possible for us to send and receive Mazatrol formatted conversational files directly over the serial port. Now all of our CNC files are safely stored on the shop computer and we don't need the little Mazak blue toaster anymore!"

— Mike Hamonds

M-Tech Machine Products, Harrison, OH

Resources

United States

24545 Lela Dr.,

Lawrenceburg, IN 47025

© 2024 Controlink Systems LLC

Website Designed & Created by Controlink Systems LLC

Customer Comments